Hot Dipped Galvanized Steel Solar Brackets

| GRT STEEL Profile for Solar Bracket | |

| Raw Material | Hot Rolled Black Steel+Hot Dipped Galvanized |

| Grade | Q235B/SS400/Q355B/S235JR/S355JR |

| Profile Type | Profile C/Profile U/Profile U Rail/Square Tube |

| Hot Dipped Zinc Coating | 65um;80um |

| Thickness(mm) | 2.0/2.5/2.75/3.0/3.75/4.0/4.75/5.75 |

Advantages of Hot Dipped Solar Mounting Bracket

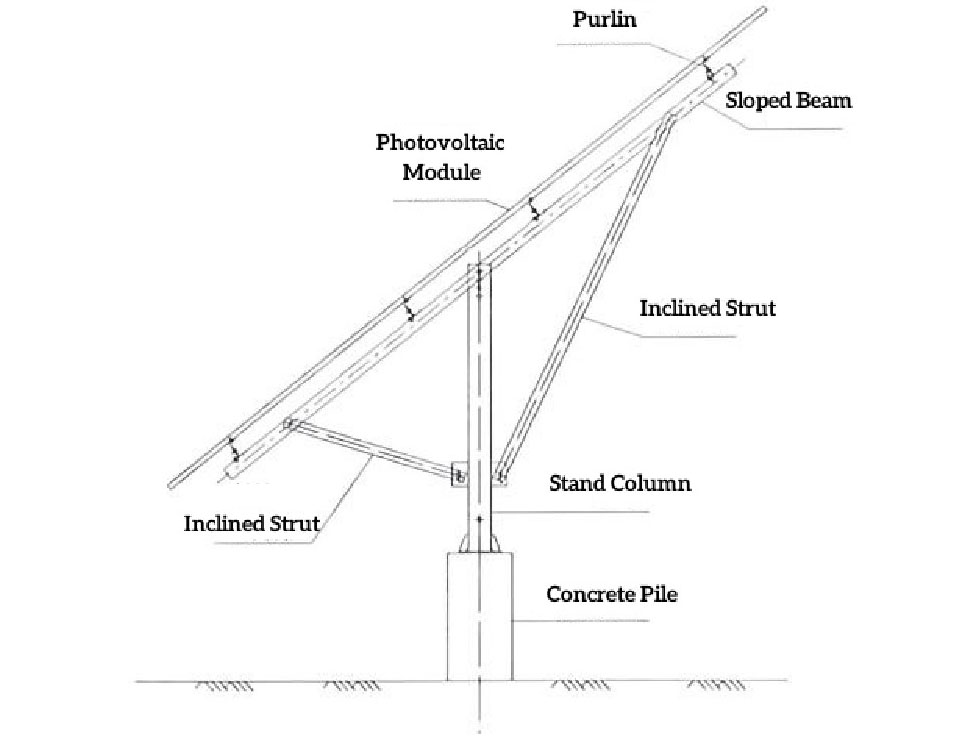

1. Enables easy, fast and cost-effective installation.

2. Flexible post spacing withstands different wind&snow loads.

3. Highly corrosion resistant surface treatment.

4. Screws and nuts go with every componts needed.

5. Fasteners and rail nut fully configured to save extra parts purchasing.

6. Mechanical calculation and reliability tested to ensure highset product quality.

7. 12-25 years system and structural guarantee.

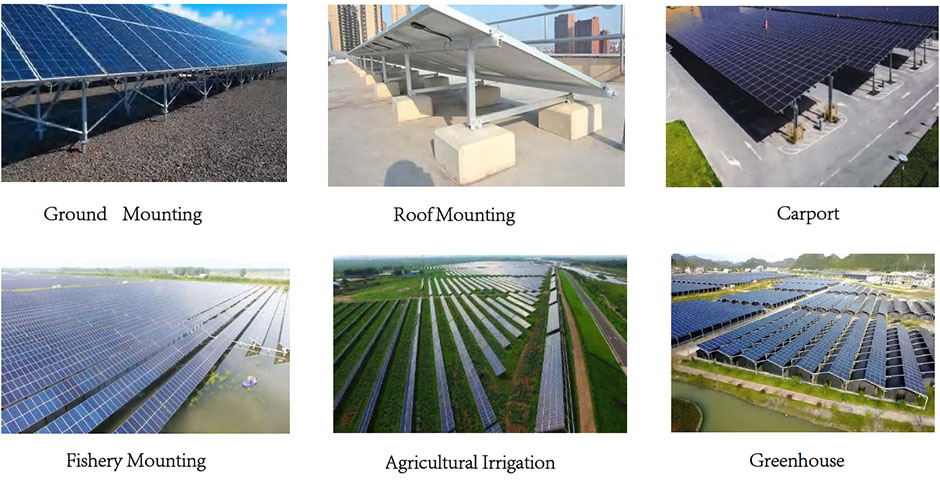

Application Scenarios

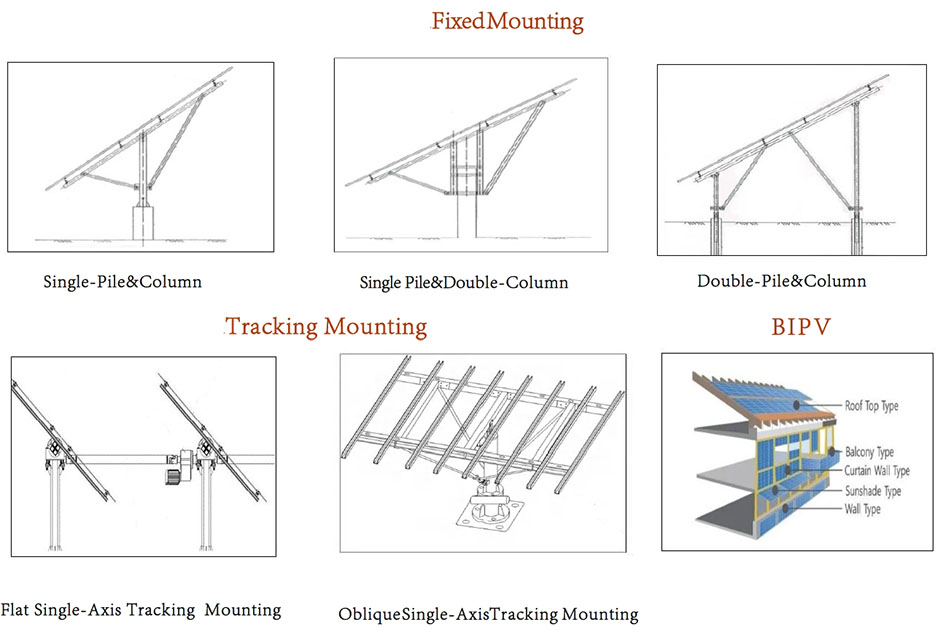

Mounting Type

Why Choose GRT New Energy?

Factorty in tianjin

GRT is a factory of manufacturing various solar modules steel support mounting brackets with the following:

● Certificate: ISO, BV, CE, SGS Approved.

● Feedback within 8 hours.

● Best price based on good quality from our own factory.

● Quick delivery.

● Stock and production are both available.

Metal Exporting For 20 Years

GRT exported various steel metal and works for decades:

● Quick delivery and waterproof standard export packing.

● Experience for many years, specialized in manufacturing and exporting.

● Customers from many country,such as North America, South America, Europe, Africa, etc.

● Flexible payment with T/T,L/C,O/A.

FAQ

1. What is your MOQ?

500kg for general products. More than 5 tons for new products.

2. Can you produce Zinc Aluminum Magnesium profiles by drawing?

We have professional engineer to design CAD drawing and establish mould according to customers' requirement.

3. What certification do you have? What's your standard?

We have ISO certification. Our standard is DIN, AAMA, AS/NZS, China GB.

4. What's the delivery time for samples and mass production?

(1). 2-3 weeks to open the new moulds and make free samples.

(2). 3-4 weeks after receipt of deposit and confirmation of the order.

5. What's the packing way?

Commonly we use shrink films or kraft paper, also we can make as per customers' requirements.

6. What's the payment terms?

Usually by T/T, 30% deposit and the balance paid before shipment, L/C is also acceptable.