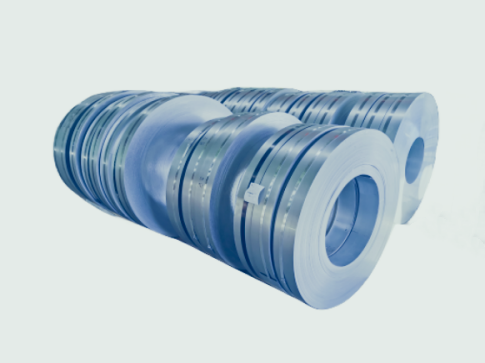

Zinc Aluminium Magnesium Steel Coils

| Standard | ASTM, GB, JIS, EN |

| Grade | DX51D-DX54D, S350GD/S420GD/S550,G350-G550 |

| Thickness | 0.3-6.0mm |

| Width | 30mm-1250mm |

| Specific Width | 136/157/178/198/218mm or "make to order" |

| ZM coating | 30-450g/M2 |

| Tolerance | Thickness:+/- 0.02mm Width:+/-5mm |

| Coil ID | 508mm,610mm |

| Coil Weight | 3-8 tons |

| Surface treatment | Chromated/anti-finger (transparent,green,golden) |

| Application | Building Purlin/Decking, Automobile, Household Appliance, PV Mounting/Bracket |

Advantages of Zinc Al Mg Steel Coils

● Because the zinc-aluminum-magnesium alloy coating is relatively thin and dense, it is not easy to peel off the coating;

● The corrosion outcome will flow and wrap the incision, so the protection performance of the incision and defect is better;

● It also has good corrosion resistance in some harsh corrosive environments (such as animal husbandry, coastal areas, etc.);

● It can replace some stainless steel with low requirements, or apply galvanizing after processing, which can simplify the user's processing process.

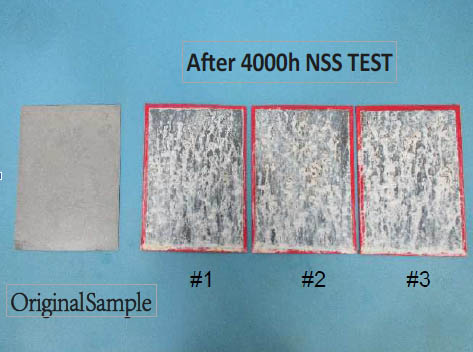

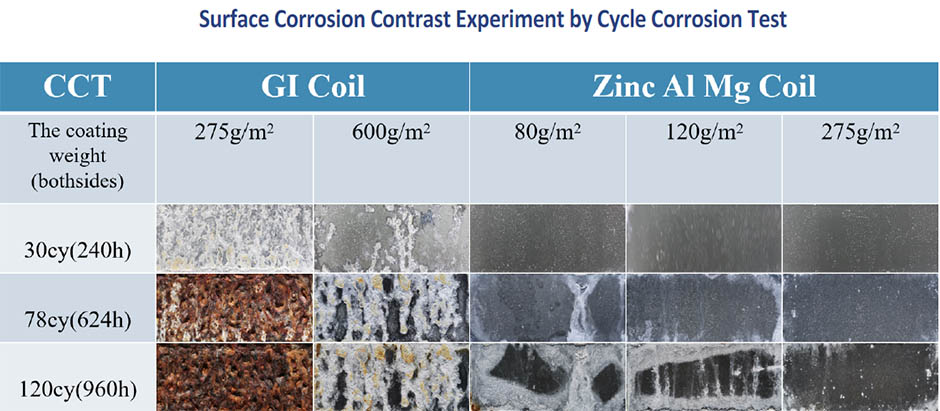

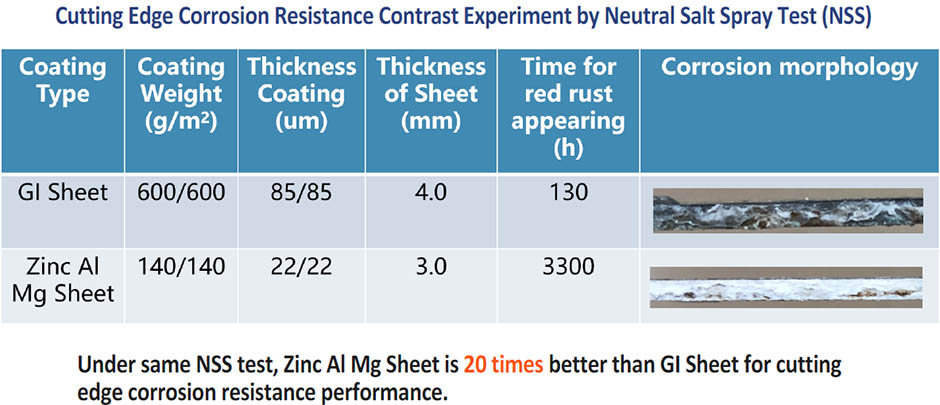

Experiment Test

Compared with traditional coatings such as hot-dip galvanized, galvanized aluminum, and zinc-iron alloys, zinc-aluminum-magnesium coatings have better corrosion resistance.

Weight of Aluminium and Magnesium

| Al and Mg Content |

Weight of Aluminium |

Weight of Magnesium |

| Low Aluminium |

1.0%-3.5% | 1%-3% |

| Medium Aluminium |

5.0%-11.0% | 1%-3% |

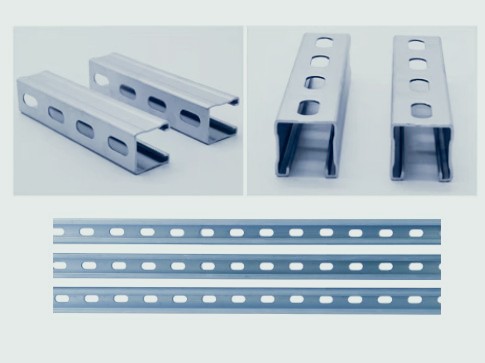

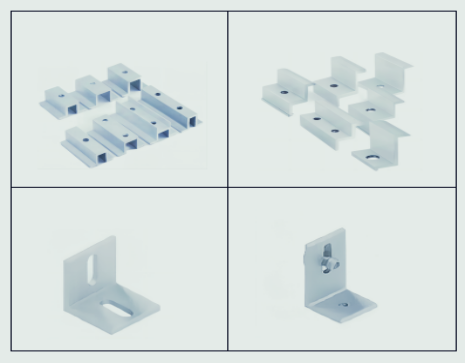

End usage

| Industry | End usage |

| PV Mounting | Solar Bracket |

| Steel Structure | C Purlin, U Purlin,Z Purlin |

| Decking | |

| Automobile | Auto Parts |

| Household Appliance | Air Conditioner |

| Refrigerator | |

| Animal husbandry | Folder Tower,Feeder,Fence |

| High speed | Guardrail |

FAQ

1. What is the anti-rust performance of the Zinc Al Mg Steel Coils?

The anti-rust performance of Zinc Al Mg Steel Coil is 10-20 times that of galvanized sheet, reaching the standard of stainless steel. This means it can withstand harsh environmental conditions and resist corrosion for longer.

2. How to reduce the cost?

The Zinc Al Mg Steel Coil is typically 40% less expensive than stainless steel, making it a cost-effective choice for a variety of applications. This is because the production process is less complex and requires fewer resources.

3. Can the Zinc Al Mg Steel Coils be corrosion-resistant and anti-rust?

Yes, one of the biggest features of this material is good corrosion resistance. It can be automatically fixed to prevent the red display, which is a common problem in other materials.

4. Does it have a good processing performance?

Yes, the Zinc Al Mg Steel Coil has excellent processing properties due to its wear and scratch resistance. It can adapt to various processing methods and maintain its integrity during the manufacturing process.

5. Is the Zinc Al Mg Steel Coils environmentally friendly?

Yes, cutting materials have passed a number of international environmental regulations and standards. It is free of harmful chemicals and can be recycled, making it a sustainable choice for a variety of applications.