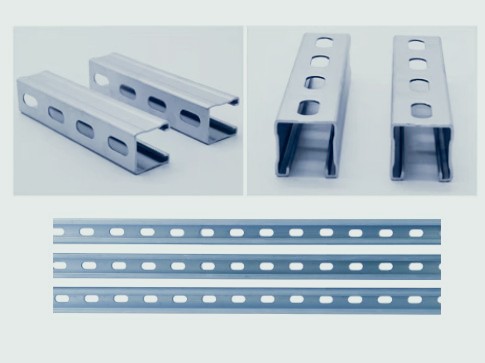

Photovoltaic Solar Mounting System Bracket Profile C

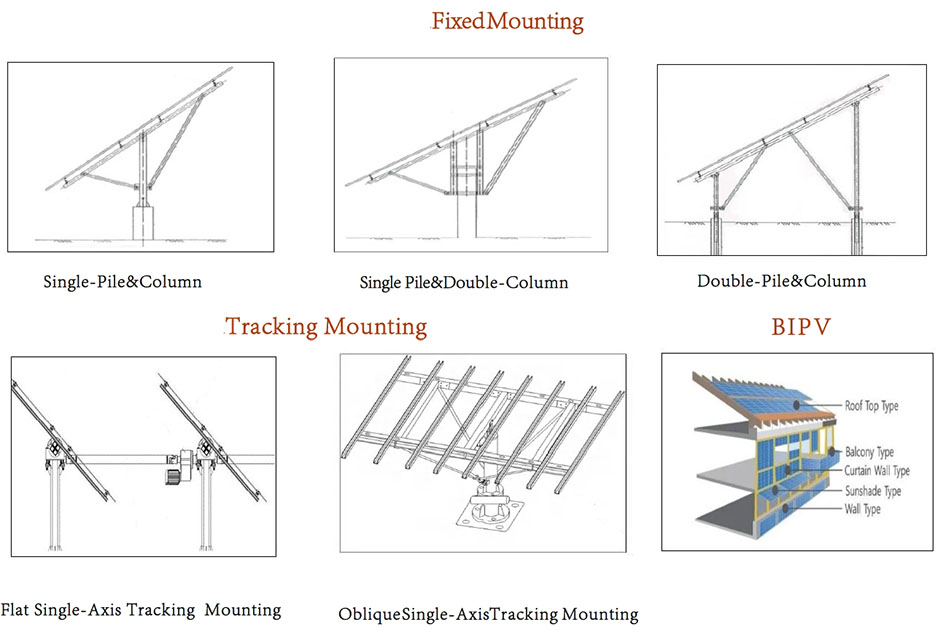

| GRT STEEL C Profile for Solar Bracket | ||

|

Raw Material | Zinc Al Mg Steel Strips |

| Grade | S350GD+ZM275;S420GD+ZM275;S550GD+ZM275 | |

| Wall Thickness(mm) | 1.5/1.8/2.0/2.5/3.0mm | |

| H(mm) | 20-400 | |

| B(mm) | 15-200 | |

| A(mm) | 8-60 | |

| Length(mm) | 5800/6000mm or fixed length | |

Advantages of Zinc-Al-Mg Solar Mounting Bracket

As solar power grows in popularity as an alternative energy source, the importance of durable and efficient mounting brackets cannot be overemphasized. Material selection is critical to ensuring a durable and successful installation. Zinc-aluminum-magnesium steel is the best choice for solar mounting brackets because it offers a unique combination of strength, corrosion resistance, and stability.

1. High strength to weight ratio

Zinc-aluminum-magnesium alloys have a higher strength-to-weight ratio than other traditional stent materials such as steel and aluminum. This means the material is lightweight but strong enough to hold the solar panels securely in place, reducing shipping costs and making installation quicker and easier.

2. Corrosion resistance

Zinc-aluminum-magnesium steel has superior corrosion resistance, making it ideal for outdoor and harsh environments. The material's corrosion resistance extends the life of the bracket and improves the overall durability of the solar panel system. Additionally, zinc-aluminum-magnesium alloys are highly resistant to sea salt and other environmental pollutants, making them ideal for installing solar panels in coastal areas.

3. Minimal maintenance

Once installed, Zn-Al-Mg solar mounting brackets require minimal maintenance, reducing overall maintenance costs and man-hours. This material eliminates problems such as rust, corrosion, and peeling paint, and requires less maintenance than other traditional bracket materials.

4. Environmental friendly

The natural composition of the zinc-aluminum-magnesium alloy makes it environmentally friendly. The material is 100% recyclable and has a low carbon footprint, making it a sustainable choice for solar panel systems. This aligns with solar energy's goal of reducing dependence on fossil fuels and minimizing damage to the environment.

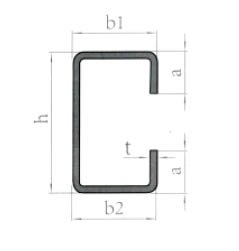

Application Scenarios

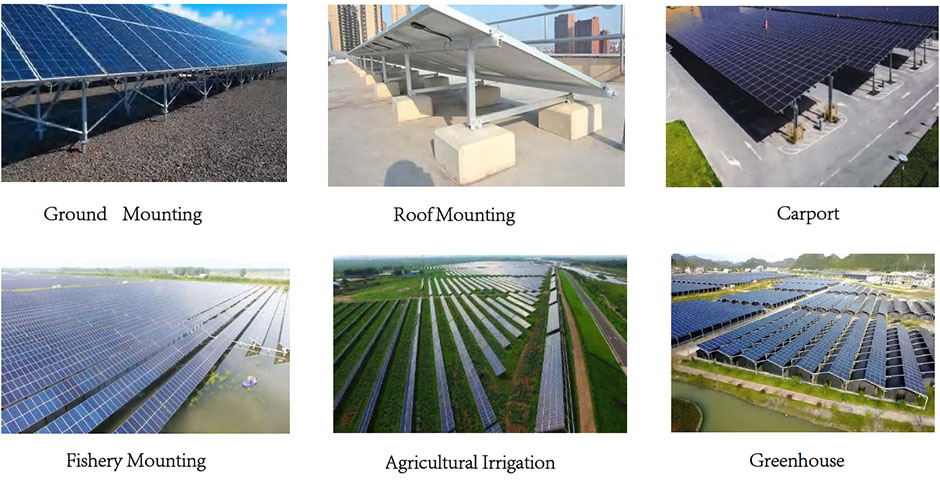

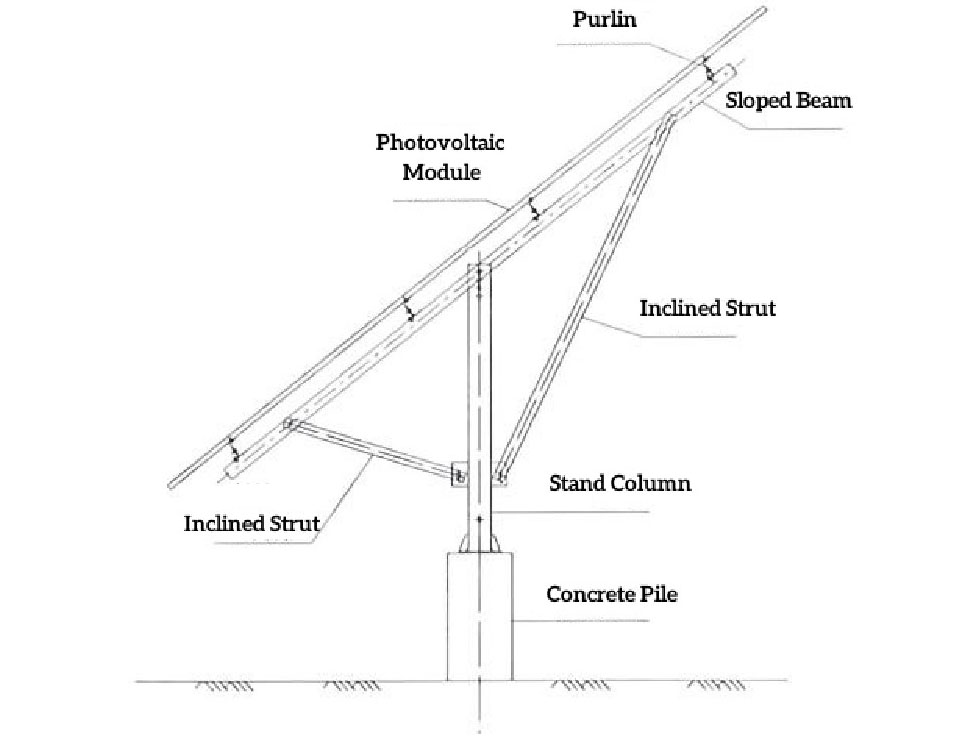

Mounting Type

Why Choose GRT New Energy?

1. Stockist of raw material

We have involved in steel business nearly 30 years. We started from simple steel trading business based in Tianjin. With years by years development, we have rich experience with steel cutting &slitting and cold bending processing.We have regular inventory of Zin Al Mg coils and strips with quantity of 4000MT around daily.

2. Factorty in tianjin

GRT is a factory of manufacturing Zin-Al-Mg Solar Bracket with the following:

● Certificate: ISO, BV, CE, SGS Approved.

● Feedback within 8 hours.

● Best price based on good quality from our own factory.

● Quick delivery.

● Stock and production are both available.

● Cooperation with Angang, HBIS, Shougang.

FAQ

1. What is your MO?

500kg for general products. More than 5 tons for new products.

2. Can you produce Zinc Aluminum Magnesium profiles by drawing?

We have professional engineer to design CAD drawing and establish mould according to customers' reuirement.

3. What certification do you have? What's your standard?

We have ISO certification. Our standard is DIN, AAMA, AS/NZS, China GB.

4. What's the delivery time for samples and mass production?

(1). 2-3 weeks to open the new moulds and make free samples.

(2). 3-4 weeks after receipt of deposit and confirmation of the order.

5. What's the packing way?

Commonly we use shrink films or kraft paper, also we can make as per customers' requirements.

6. What's the payment terms?

Usually by T/T, 30% deposit and the balance paid before shipment, L/C is also acceptable.